Out of the Camp Ch. 14 – The Seahawk

I didn’t mention earlier that the lady complaining about muddy boots on her carpet was one of Murray Mackie’s customers and he’d certainly made his feelings clear when he heard about this. Mrs. Fleet had taken his call one day while I was out and had passed on the message later that evening. She said, “they’d had words”, whatever that meant but it didn’t sound good. I’d attempted to return his call the following morning, but he wasn’t available. I didn’t think much more about it as I was so busy trying to keep on top of things. I had arranged to meet the RAF tech early one morning at a local café and after looking over his resume I asked one or two questions and basically told him what was going on. He’d obviously read the article in the paper about the ship antennas and asked about the job. I told him I hadn’t really thought about hiring anyone at this stage but that I thought he might be able to help me with a problem that had arisen. Two of the antennas had stopped working and I asked if he thought he might be able to fix them. We could work something out on a sub-contract basis, and he could freelance which would leave him open to find something else fulltime. We reached an agreement, and he came around to the office to pick up the antennas which I’d removed from the vessels, and he took them home with him to his workshop. I’d no idea at that stage quite how I was going to resolve any warranty issue that a customer might raise. Neither had it occurred to me to mention it in my dealings with the suppliers. I needn’t have worried because I learned as time went by, that equipment exposed to the elements at sea had very limited warranties, and mariners and companies just expected to pay up when anything went wrong unless the gear was leased.

I was still running all over the place with Bruce installing and servicing domestic systems and more and more frequently finding myself up ship’s masts messing with my mushrooms. For those of you who’ve been following me on this journey you may remember me talking about the need to develop a head for heights while climbing around on very high buildings in central London and the West End. Well, when you attempt to employ those skills in a maritime setting there is an additional element that has to be taken into consideration. Weather! Or more specifically, winds, particularly gale force winds. And did I mention that there are hardly any trees in Peterhead? I’m convinced that it’s because of the winds; that they get torn out of the ground as saplings, never having stood a chance of survival in the first place. Well, I found myself up a ship mast on more than one occasion in a force nine gale, swinging sickeningly from side to side and hanging on like I’d never hung onto anything in my life. But, hey, you can get used to anything, right? These challenges usually took place on supply ships which are normally leased and as such need to be working to generate revenue. Meaning that when a ship has docked to either load or unload cargo, typically it must be underway again within eight hours. So, waiting for good weather before climbing the mast to fix an antenna wasn’t an option.

One morning I walked into the office and Mrs. Fleet said that I had to ring Murray Mackie the minute I arrived. He’d been on the phone again and was fit to be tied about something. I asked her if he was “still banging on about that bloody carpet.” I’d forgotten all about it, anyway she said that she didn’t know. I was thinking, “Who needs this crap? The guy’s only given us 3 or 4 damn jobs. I felt like telling him to stuff it!” Anyway, I called him, and it wasn’t about the carpet. Apparently one of his customers complained to him about Mrs. Fleet. The customer (I’ll call her Mrs. Lovie) had bought a TV from him and was calling us to schedule an appointment to have the aerial erected. It turned out that Mrs. Fleet knew her and was teasing her (my choice of word) about getting a TV installed but Mrs. Lovie didn’t appreciate the humor. Mrs. Fleet had said something to the effect of, “What are you needin’ wi’ a TV? Ye need tae roll up yer sleeves and clean that damn hoose o’ yours, an’ I hear that yer man’s getting’ tired o’ egg and chips every night. Whit aboot cookin’ him a decent meal fur a change?” As someone once said, “It takes a village”. I was having a hard time keeping a straight face, but he got my attention when he said that either I get rid of Mrs. Fleet or we’ll get no further work from him. I realized that this guy knew a lot of people in the area, including fisher families, and could if he wanted to, cause us a lot of problems. I apologized and told him I’d take care of it but in fact, did nothing.

A few months passed and business was steady. I was still managing to keep up with the domestic installations and service calls working with Bruce, the ship’s aerials were selling like hotcakes and we also now had a regular business repairing the ones that broke down. The ex-RAF tech, Dave, had figured out a way to dismantle them, get inside, diagnose and resolve the problem, and seal them back up again. We were also now shipping new units for resale to marine electronics companies all over the UK. I was starting to think about how we could get into the business of making these things ourselves. Having seen the aerials dismantled it didn’t seem that there was a great deal involved in their manufacture and so shouldn’t be too difficult to emulate, provided we could overcome the biggest obstacle which was the casing. Coincidentally, Mary’s parents had a friend who was in plastics and had two factories one of which was in in Cheshire. I knew him from meeting when we’d go to her parents for the odd weekend and he would often take everyone out for Sunday lunch. I called to sound him out about the possibility of manufacturing the casings for us and he was sufficiently intrigued to suggest we meet to discuss it next time the family were in Manchester. We already had a trip planned and were going to be there the following week and so we arranged to meet up then. Before we set off that weekend, I put a defunct unit into the trunk (boot!) to give to him, along with some technical data on the equipment. Basically, it had a shell-like configuration made up of two halves, the lower section incorporating a ‘collar’ designed to support the unit on top of a pole or mast.

The make-up of the unit (n.b. if you’re not interested in technical stuff, then you could skip this paragraph if you wanted to!) comprised the casing described above. Inside there were a series of copper rings functioning as aerials connected to a signal amplifier in the form of a microchip which, in turn, connected to the coaxial cable that was fed through the collar of the unit, down the inside of the mast and ultimately to the power supply unit by the TV. Holding the interior components in place and also helping to waterproof the interior, was a polyurethane foam filler which was injected through a small hole in the top half of the ‘mushroom’, and then sealed. Holding the upper and lower sections together was a silicone sealant reinforced by a series of rivets shot into the upper rim which had a small lip that curved over the slightly smaller rim on the lower section.

We met in the Horse & Jockey pub in Manchester, and I’d prepared some financial data and laid out the whole situation including our shortage of cash despite our increasing sales, advanced orders and projected figures based on the short history of the business as a whole including the service side. Of course, the focus was on the potential of the ship’s antennas and I managed to convince him, based on sales and advance orders, that there was a future for the business, especially since there was no other manufacturer of these antennas in the UK. Also, satellite TV, especially at sea, wasn’t even on the horizon at that point in time, and satellite navigation systems were in their infancy and restricted to very large vessels and high-end luxury yachts. After clarification of a few technical issues, the final design of the units and an agreement on extended credit to enable us to get this off the ground, we were in business as a manufacturer within a couple of months. I managed with the help of a patent agent to get a Patent Pending number to provide us with some protection against imitators, and also license the name of the unit, ‘The Seahawk’, with a trademark for the product. You might think it’s a bit of a cheek that we would be applying for a patent when we’d pinched the idea from the Germans, but the truth is that, yes, we’d gotten the idea from them, but we designed our own unit which had a completely different appearance and the accessories such as the PSU and distribution units were assembled and encased in standard item electronics plastic accessory boxes. And anyway, ours had a much cooler name!

‘The Seahawk’ really took off over the next two or three years and there were a lot of other developments during that period. We’d had to find larger premises and were lucky in that our bank had a small office suite next door that was available. It had a reception area with a couple of small offices and a larger room which was a perfect size for our antenna assembly operation.

Dave was now a full-time employee and kept busy assembling and repairing the antennas in addition to working on marine radios, radar, sonar and other electronics mainly on the fishing fleet. In fact, we ‘d gotten so busy that from time-to-time he’d call in a pal, another ex-RAF tech to give him a hand and so he now, in turn, became a part-timer.

I was now living with the family in MacDuff, about 55km from Peterhead, on the Moray Firth, having bought our first home for £7,000, as there was still a housing shortage in Peterhead due to incoming workers. It was a three storey house with four bedrooms which now seems incredible, but the rooms were small, and it was a small fishing village, and it was a long time ago and I’m feeling very, very old!

At the time, there was a supply boat company in Peterhead called Jackson Marine and we’d done a few service jobs for them on VHF radios. Their electronics supervisor, a guy called Phil, would come into the office from time to time and one day, walked in and ordered 22 Seahawk Antennas for the whole fleet. They didn’t want them installed, they’d do that themselves, just delivered to their base in Great Yarmouth. I was blown away by this and we struggled to finance the purchase but, thankfully we’d found a very helpful bank manager in MacDuff who we’d already transferred all our business to, from our prior Peterhead bank, who was still our current landlord. The MacDuff manager knew who Jackson Marine was, a subsidiary of Brown & Root (the name they were known by then), a Halliburton company. So, there wasn’t much risk; the only problem I was to learn over the coming years, was their custom of dragging their feet when it came to paying bills, which plays havoc with your cashflow. You can put as many conditions as you like on your Terms of Business, but if these guys don’t want to pay you in 30 days, they won’t. You’ll get your money when they’re ready to cough up. I will say though, that it helps to chase them up from time to time. They’ll tell you the cheque’s in the mail or they’re going out on Friday, or whatever. Sometimes it’s true and sometimes not. If you’ve got a good relationship with your contact in the company, they’ll usually have a word with the accounts payable people and get them to expedite payment.

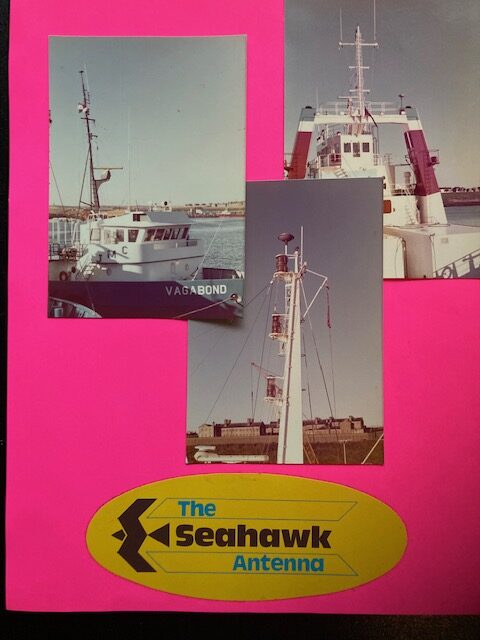

Images.

(1) International Seahawk Marine TV Antenna w/PSU + Splitter. (2) Offshore Supply Vessels, two with International Seahawk units and the ‘Vagabond’ vessel on the left with the Basic domestic model on top of the mast.